Thin Double Glazing

Available in 4 types: D10, D11, D12 and D13. Each providing varying acoustic and thermal insulation properties. The inner pane has a Low Emissivity coating, the cavity is gas-filled and the outer pane can be chosen from any of our glass types.

In existing frames the rebate should be at least 16mm deep and 8mm wide. For new frames, the optimal depth of the rebate is 18.5mm, the width of the glazing bar 24mm (with a 10mm rebate width).

Why don't we use warm-edge technology?

Warm edge technology is now standard for conventional double glazing, and the required width of up to 18 mm for the edge seal is well hidden in large rebates. For historic windows this is of course not an option.

Because of the width of the glazing bars, the perimeter seal needs to be much smaller, which unfortunately cannot be achieved with warm edge technology without compromising the quality.

Our solution

The only reliable way to ensure consistent quality in the production of our units is to work with a primary seal which sticks the 2 panes of glass to the aluminium spacer bar, with a secondary (perimeter) seal to make sure the unit retains the gas. This combination makes our perimeter seal 7-8mm. If we could use different materials to reduce this and still be able to guarantee the longevity of our product, we certainly would. After 25 years of testing, though, we haven’t found a way yet!

Over the past 25 years our research and development team have tested and compiled independent test data for many sealing systems. This knowledge has enabled us to construct a product that achieves all parts of the BS EN 1279 standard (parts 1-6) as defined in the European legislation Product Directives.

Does the aluminium spacer bar create a cold bridge?

All materials have thermal conductivity, some higher than others. Aluminium and glass individually have a relatively high conductivity and if the aluminium spacer bar touched the glass directly, it would most certainly create a cold bridge. However, this is not the case as the primary seal provides a bridge between the two products and as the thermal conductivity of this seal is negligible, the cold-bridge effect is also negligible.

- Total thickness of units starting at 10mm

- The only system of its kind to conform to all 6 parts of BS EN 1279.

- Covered by a 7 year manufacturers warranty.

- For the outer pane please select from our section glass types for all options and more information.

- We recommend installation using putty to obtain the look of single-glazed units. We supply a specially developed, non-linseed based sealant and putty for the installation of the units to guarantee the highest possible quality.

- The aluminium profile can be coloured in any RAL-colour to match the colour of the paintwork of the frames.

- Low-E float glass inner pane

- Gas filled cavity

- Outer Pane

- Aluminium spacer bar

- Perimeter Seal

- Sealant - Kawo Elastokit

- Hardwood spacer

- Sprig

- Putty line - Kawo Elastokitt

- Paint overlapping onto glass by 1-2mm

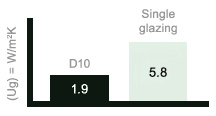

D10

Thickness

3-4-3mm (10mm)

Thermal Insulation

A decrease in energy-loss of ≈ 67% compared to single glazing of which ≈ 5.8 W/m2K

Weight

15kg/m.sq

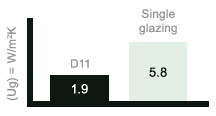

D11

Thickness

3-4-4mm (11mm)

Thermal Insulation

Part L = Eng/Wales

Part J = Scotland

Noise Reduction

34dB (with test certificate)

Weight

17.5kg/m.sq

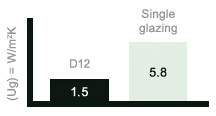

D12

Thickness

3-6-3mm (12mm)

Thermal Insulation

Part L = Eng/Wales

Part J = Scotland

Weight

15kg/m.sq

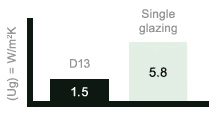

D13

Thickness

3-6-4mm (13mm)

Thermal Insulation

Part L = Eng/Wales

Part J = Scotland

Weight

17.5kg/m.sq